Lesson Modules

Teaching Tips:

Module Overview

Quick introduction to the concet of the lesson.

Lesson Overview

• Teacher will grab student’s attention by asking them reflect on lesson 6.

• Students will plan and make changes to their project as well as take pics and video of the process.

• Students will create a report describing the planning, challenges, and changes they made to make assembly more efficient

Materials Needed

Lesson 8 Project Planning - 1st Robot

Lesson 8 Project Planning - 2nd Robot

Detailed explanation of the code solution

Teaching Tips:

Explore Module Overview

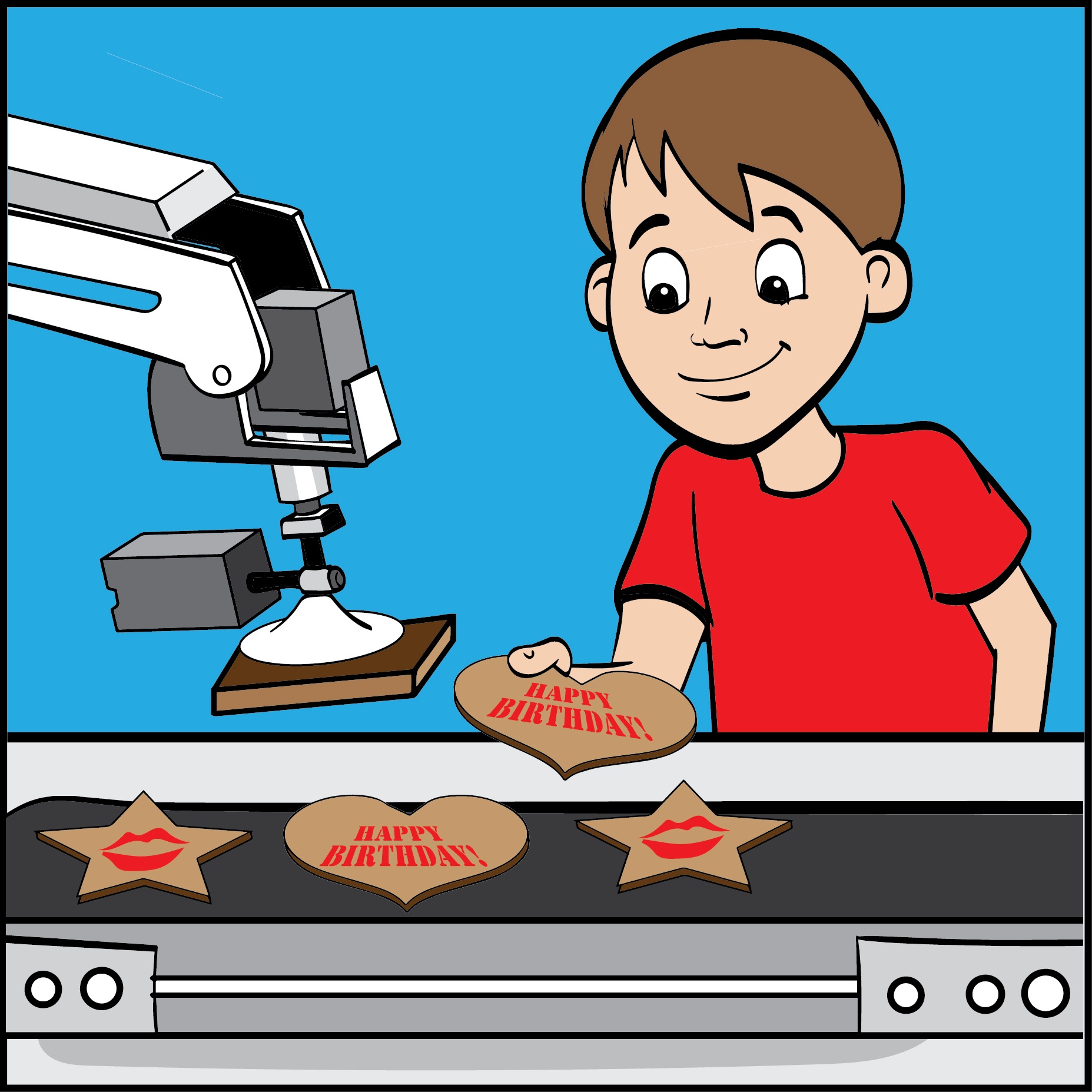

• Students discover how multiple robots are used for creating retail products in the real world using a collaborative assembly line.

• Students will discover the pros and cons of this type of assembly line

• Students will learn to test the code and trouble shoot with efficiency of the system

• Students will learn how to plan and discuss with others on how to improve and make systems more efficient

Questions to Facilitate Discussion

- What does collaborative mean?

- What are the pros and cons of a collaborative assembly?

- What were some of your biggest tasks in the project?

Higher order thinking question

- What else could you have done to make project more efficient?

For this last STEM challenge you will plan together with your partners from Lesson 7 on how to make the project more efficient by using humans. Once you execute the plan you are to time the difference the whole process takes to make the same amount of product.

Think and plan carefully about what part of the assembly line can be done much quicker and efficiently by one of your partners.

Both robots must still be used in the process. Companies do not like wasting money!!

Teaching Tips:

Prototyping Module Overview

Each group or individual is to program Dobot with the following guidelines:

- 1st Dobot will vary on the changes the students made

- 2nd Dobot will vary on the changes the students made

- There will be human involvement in the manufacturing process

- The process will be repeated

Think and plan carefully about what part of the assembly line can be done much quicker and efficiently by one of your partners.

Both robots must still be used in the process. Companies do not like wasting money!

TIP: You might want to try just dropping the product as it stacks to save time and coding. Dobot can be very precise in dropping. If you had already discovered that in the previous lesson props to you!

Teaching Tips:

Reflect Module Overview

Take this time at te end of the course to reflect on the whole experience. Students may want to infomally present their projects and show off the unique change they made to the manufacturing process.

Questions (answers will vary)