Lesson Modules

Teaching Tips:

Observe Module Overview

- Teacher will grab student’s attention by asking them to look at a power point and video of a robot arm utilizing a visual color sensing attachment to identify an object by shape or color. They are to ask themselves what is happening and what technology is being used. While at the same time the teacher will be demonstrating how it’s being used in a real-world situation.

- After video and power point lesson, students will program the Dobot to simulate the automation of sorting the toxic containers (or other objects) by color using the color sensor.

- The student’s, after the engagement, should be asking themselves how they can apply what they just learned in future project given by teacher and in the real world.

Lesson Overview

- Ensure the Dobot firmware and software is updated to the latest version. This will reduce troubleshooting.

- This lesson can be done individually or in groups. Depending on size of class or number of robots. If several students per robot, you might want to assign them separate responsibilities for full engagement.

- This lesson can take between 1 to 2 class periods depending on coding knowledge of students with Blockly ,Script, and Dobot in general.

- This lesson and skills is considered medium and will be built upon to higher levels in the next lessons.

- Having students start in the Power ON homing position is recommended, so that every student or group has their Dobot(s) start from the same spot.

- Remind students that in this project they are to pick an x,y,and z coordinate spot where they will be feeding Dobot the cubes.

- The perfect distance between the suction cup and cube will need to be determined by students for optimal suction.

- When programming remind students about turning on and off the suction cup as they do with the gripper attachment.

- We included a code sample of the process as show on video. Some of the commands have comments for your guidance.

Materials needed

Blank paper to draw on

Detailed explanation of the code solution

Optional materials

Key factor vocab sheet to print

Construction Robots

Construction companies are embracing and welcoming their new high tech workers. Who are they?

Teaching Tips:

Explore Module Overview

- Students discover how robots are used for building and construction in the real world

- Students learn different category of construction robots and the pros and cons of these systems

- Students will explore the limitations of robots such as Dobot when building and its height limits

- Student should be able to explain the new (VOCABULARY) they have learned and how it’s applied.

Questions to promote discussion:

- What does semi-autonomous mean?

- What other types of jobs can you think of for construction robots?

- Do you think companies really do leave construction robots working Why or why not?

Higher order thinking question:

- What other type of robot can you think of that can benefit humanity?

Teaching Tips:

Each group or individual is to program Dobot with the following guidelines:

Programming Challenge

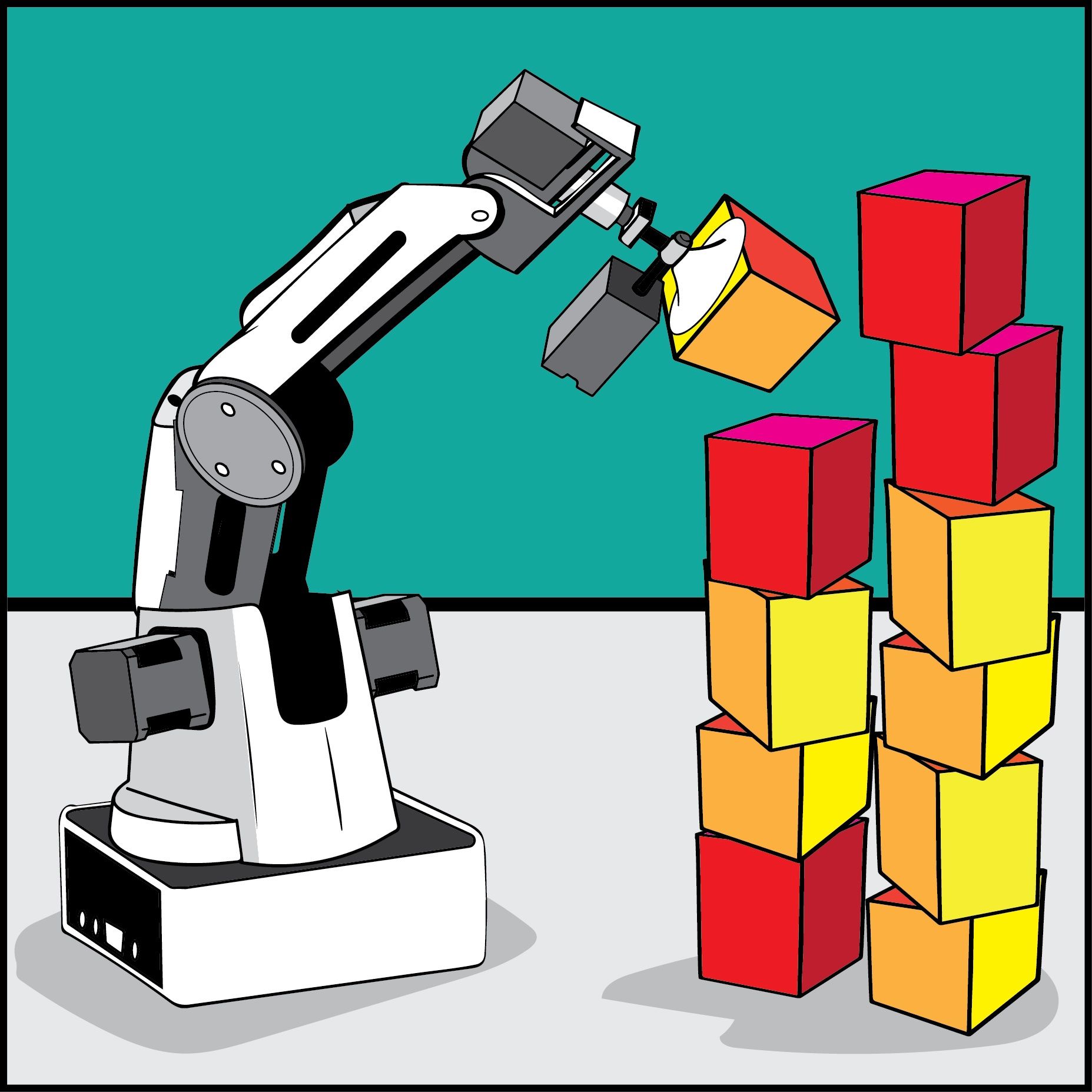

You will program DOBOT to build a tower as quickly possible.

Who will build the tallest tower in the fastest time!

Sound easy right?

Not so fast!! Remember, Dobot must increase its height (Z coordinate) each time it drops a cube as it is building. How can you increase the height each time?

Hint: Create a variable for your height

Hint: Faster is not always better. You have to find that perfect setting where your robot works quickly, precise, and efficiently.

Teaching Tips:

- Why are robots many companies struggling to find construction workers?

Many workers don’t like to get dirty and work in the hot sun. Many people want clean jobs and in office where they can stay cool and safe.

How many bricks could SAM lay down in one day? Compared to humans?

- SAM can lay 3,000 compared to about and average of 1,000 with humans.

What kind of robot is SAM categorized as?

Traditional Semi-Automated

Who are the people not fearing job losses when it comes to construction robots?

Robotic Engineers and programmers.

Name some of the benefits construction companies are having because of these robots over manual labor.

- Highly precise, repeatable, superior uptime (no breaks), fast working, and meeting deadlines.

What are the three kinds of construction robots in existence right now? Describe each.

Traditional, Robotic Arms, and Exoskeleton

What is the drawback of the exoskeleton robot?

Battery doesn’t last all work-day

Reflect on your project . How many failed attempts did it take? What was the perfect value of the variable for the Z axis (the offset)?

- Answers vary

What new things did you learn during the project?

- Answers vary

- Robotic Arm

- Traditional Semi-Automated

- Robotic Exoskeleton

- 3000 / 1000

- 3000 / 3000

- 1000 / 3000

- 1000 / 1000

- No drawbacks!

- More expensive than other robots

- Takes a long time to train people

- Battery doesn't last all day