Lesson Modules

Teaching Tips:

Observe Module Overview

- Teacher will grab student’s attention by asking them to look at a video of a robotic arm handling HAZMAT conatiners.

- Ask students what is happening and what technology is being used.

- Explain to students that in this lesson they will program the Dobot to simulate the task of HAZMAT automation.

Lesson Overview

- Ensure the Dobot firmware and software is updated to the latest version. This will reduce troubleshooting.

- This lesson can be done individually or in groups. Depending on size of class or number of robots. If several students per robot, you might want to assign them separate responsibilities for full engagement.

- This lesson can take between 1 to 2 class periods depending on coding knowledge of students with Blockly or Script.

- This lesson and skills is considered basic and will be built upon to higher levels in the next lessons.

- Having students start in the home position is recommended, so that every student or group has their Dobot(s) start from the same spot.

- We recommend you place the PICK and PLACE handouts at a similar position and distance from the Dobot to prevent Range Limit ERRORS! Make sure students are aware and remember the working area and limits of Dobot. This will prevent errors and reduce troubleshooting time allowing the lesson to completed quicker. TIP! Tape some of the corners to prevent paper moving!

- Let students know that utilizing the SetJointAngle command is more efficient and error free when setting Dobot in an ARC motion as in this project simulation. This helps students learn more about Dobot, software, and making Dobot working efficiently and less prone to errors. Many students will try programming dobot to move from one end of the arc to another just using the MOVE command, which will very likely result in “Mov Limit Alarm Triggered” errors!

Materials Needed:

Here is a lesson plan for your records.

Print this chemical handout students will need during the Prototype module.

Use this code solution as a reference for grading.

Here is a detailed explination of the code solution. It is useful to help students who are stuck in the prototyping process.

Optional Materials:

Print this Key Factor vocab sheet to use as a reference dring class.

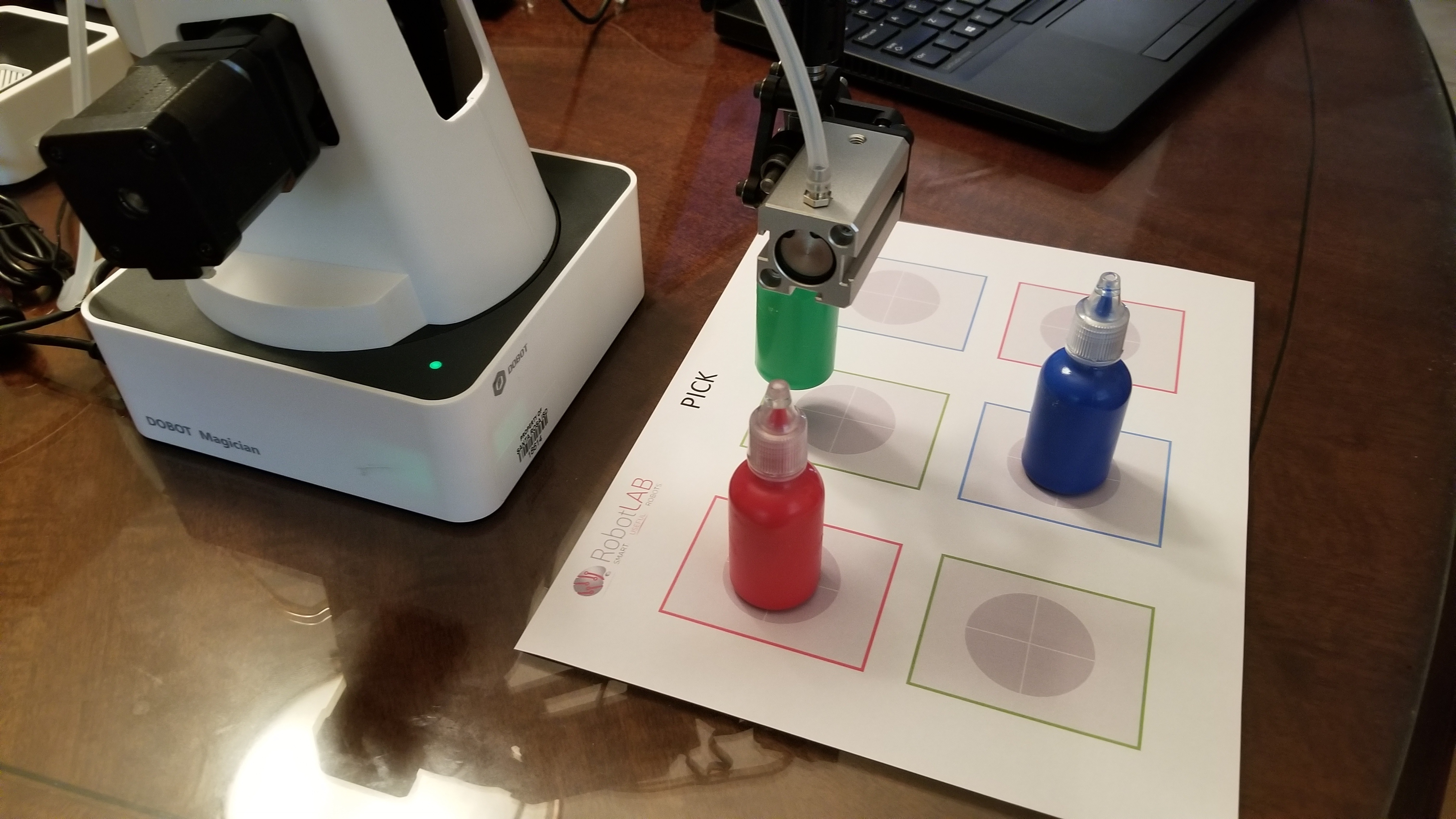

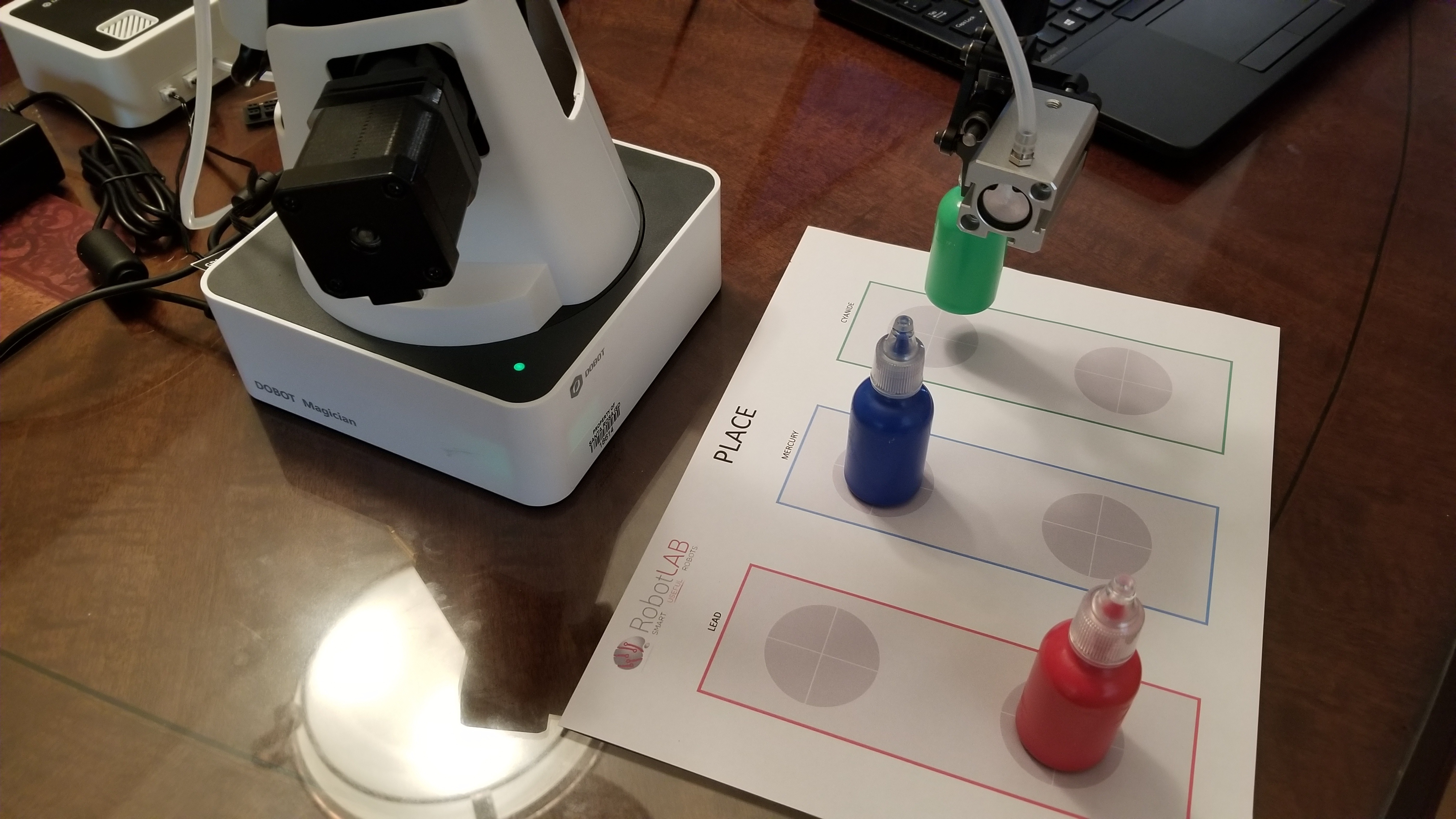

You can use the colored cubes that come with conveyor belt. To make the project scenario more realistic we recommend small colored containers like the ones shown here. These containers (fabric paint) were purchased at Wal-Mart for $1 each and the labels were removed.

Teaching Tips:

Explore Module Overview

- Watch the video.

- Read the key factors as a group.

- Answer the questions individually.

Industrial Robots

- 2.0 Kg

- 3.0 - 5.0 Kg

- 1.65g - 2.5 K

- 5 Kg

- Horizontal

- Vertical

- Both

- Neither

Teaching Tips:

Prototype Module Overview:

Before the prototyping begins, students should be able to explain the new EOAT (VOCABULARY) they have learned and how it’s applied.

Check for understanding by asking questions such as:

- How does a mechanical gripper work?

- How can it be applied in a real world product or situation?

- Where are mechanical grippers used these days?

Higher order thinking question:

- How can you design the robot arm and/or assembly line to work more efficiently?

Each group or individual is to program Dobot with the following guidelines:

- Dobot must accurately and safely PICK up a container

- Dobot must securely transport the container to the appropriate labeled colored PLACE without dropping it.

- Dobot must safely and accurately place down the container inside the circle without touching the outside.

Prototyping Challenge!

In groups or individually, program DOBOT to simulate the handling of HAZMATs like you just learned. You will program DOBOT to handle toxic containers and place them in storage securely and safely.

Place the PICK handout in front of Dobot and the PLACE handout on either side of Dobot.

PICK PLACE

If you need extra help to visualize the task, here is a video of Dobot performing the completed project: completed project video

Teaching Tips:

Reflect Module Overview

Facilitate a discussion on the many benefits of using automation

- Safety

- Speed

- Accuracy

- Handling toxic materials

Review key vocabulary.

- Load

- Work area

- Cycle time

- Repeatability

- Planes of operation

Have students reflect and rate their performance as robot programmers.

- How many failed attempts?

- How much time?

- What was the perfect speed setting?

Discussing on how much time it might of taken programmers in the field to get everything working as efficiently and safely as possible.

Questions & Answers

- What is the most important justification for companies when investing in robots for HAZMATs?

Shielding people from working in dangerous environments and HAZMAT.

- What is HAZMAT? Provide some examples.

An abbreviation for hazardous materials.

Toxic chemicals, fuels, nuclear waste products, and biological chemicals are some examples.

- Companies use robots to reduce what? Can you think of other reasons why?

They want to reduce potential liability for workers’ compensation.

Also, to reduce other costs associated with worker exposure.

- Name two key factors companies take into consideration when deciding on type of robot. Describe each of them.

The answer can be any of the vocabulary terms in the KEY FACTOR VOCABULARY handout.

- Dobot is a four-axis robotic arm. Most companies use a six-axis robot or higher. What is a six-axis robot and what are the advantages?

Six axis robots allow for greater flexibility and movement allowing to perform a wider of tasks compared to one with fewer axes.

- Reflect on your project . How many failed attempts did it take?

- What was the perfect speed setting for your robot?

- Do you think the robot programmers at these companies had to go through similar steps as you did? What do you think they had to do differently than you?

Answers will vary.

- 1-3

- 4-6

- 7-9

- 10+