Lesson Modules

Teaching Tips:

Observe Module Overview

- Teacher will grab student’s attention by asking them to look at some pictures with a question.

- Discuss the possible improvements students have aleready been thinking about.

Lesson Overview

- Ensure the Dobot firmware and software is updated to the latest version. This will reduce troubleshooting.

- This lesson can be done individually or in groups. Depending on size of class or number of robots. If several students per robot, you might want to assign them separate responsibilities for full engagement.

- This lesson can take between 1 to 2 class periods depending on knowledge of students with Dobot and software in general, and the design of their project.

- This lesson and skills are considered minimum. This project requires troubleshooting hardware, software, and their overall project design and planning to improve product as stated in the challenge.

- Have students provide details of the steps in the handout included

- Keep reminding students about their glasses and safety rules to prevent injury!

Materials Needed:

Here is a lesson plan for your records.

Print this Process Optimization handout.

Optional Materials:

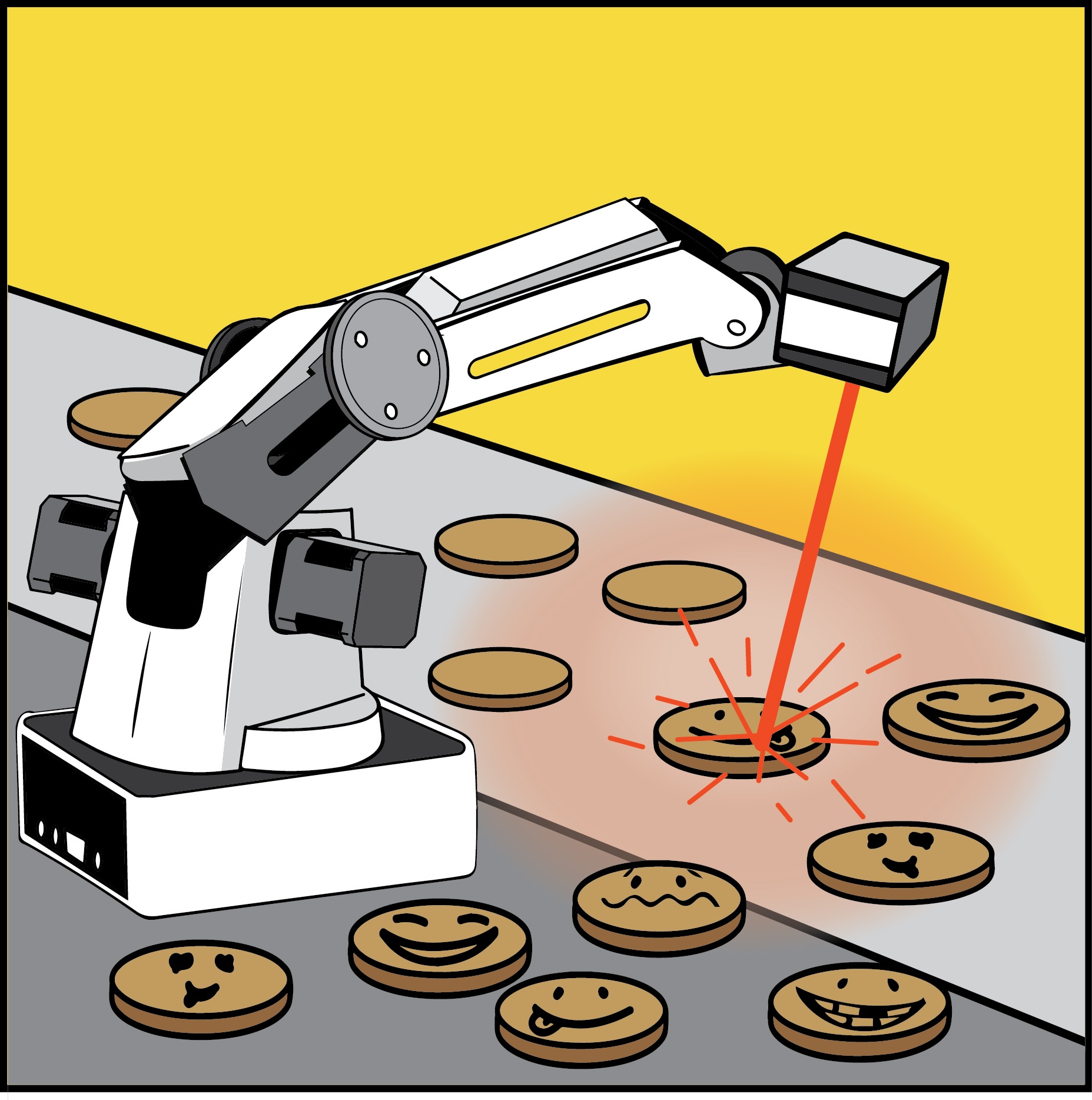

Now that you’ve made your first custom product. Have you found yourself saying “I should have used this material this instead!” or “I need to change this!” or “Next time how can I make it better?”

That is Process Optimization.

Teaching Tips:

Explore Module Overview

- Students discover the steps of process optimization taken in the manufacture industry

- Students will be able to explain what the optimization process is and the steps taken

- Students will practice the steps taken in process optimization to improve their product and processes

- Students learn problem solving using robot, software, planning, design, and cost effectiveness of their product

- The teacher will check for understanding by asking questions

Questions

- What is process optimization?

- What steps are necessary?

- What can I improve?

Higher order thinking question

- How can I automate the process?

So what are the process optimization steps?

Remember the main goal is to reduce time and resource wasting, over spending, bottlenecks, and mistakes while achieving that goal.

You might be saying “Yeah, but how do I get there?”

Teaching Tips:

Prototype Module Overview

Each group or individual is to design and improve their product with Dobot and process optimization.

- Project from lesson 4 must be improved and notated in detail on the handout

- Must show evidence of steps taken to improve process and project

Teaching Tips:

Reflect Module Overview

- What is Process Optimization?

- outcome of process optimization should be reduce money, time, and resources spent in the manufacturing processes leading to positive results.

- Companies everyday are faced with what challenge?

- Companies everyday are faced with the challenge of making more for less.

- Name at least 4 of the process optimization steps mentioned and describe them.

- IDENTIFY – First, you need to identify the processed that exists with your product or company. What is costing you more than it should or upsetting your client.

- RETHINK - you need to rethink the targeted process, rethink it, and ask yourself questions.

- IMPLEMENT –time to apply the process in a new way.

- AUTOMATE – Automate the process that worked and check to see if it helps you with cost reduction, prevent mistakes, cut wasting and production increases.

- MONITOR – You always need to monitor the entire process optimization. After the automation, you will sure find new improvement area and bottlenecks. Identify them, rethink the process, implement it and automate it. This is a cycle project.

- The outcome of process optimization should be ….?

- The outcome of process optimization should be reduce money, time, and resources spent in the manufacturing processes leading to positive results.