Lesson Modules

Teaching Tips:

Student view answer: The Manufacturing Process

Manufacturing process are the steps through which raw materials are transformed into a final product. The fundamental goal of manufacturing process is to produce a product that has a useful form. Transportation, handling or storage of parts are not under steps of manufacturing process, because these steps are not involved with the change of form of material or dimensions of the part being produced.

Observe Module Overview

- Teacher will grab student’s attention by asking them to look at some pictures with a question

- The student’s, after the engagement, should be asking themselves how they can apply what they just learned in future project given by teacher and in the real world.

Lesson Overview

- Ensure the Dobot firmware and software is updated to the latest version. This will reduce troubleshooting.

- This lesson can be done individually or in groups. Depending on size of class or number of robots. If several students per robot, you might want to assign them separate responsibilities for full engagement.

- This lesson can take between 1 to 2 class periods depending on knowledge of students with Dobot and software in general, and the design of their project.

- This lesson and skills are considered minimum. This project requires troubleshooting hardware, software, and their overall project design and planning to create their product as stated in the challenge.

- The lesson recommended some items and materials needed for completion of lesson, but you may use other materials or design if the objective of the lesson can be accomplished.

- Come up with a list of materials and their costs. Choose materials that you can find easily in your classroom, and allow groups to “buy” what they need to make their product

- Keep reminding students about their glasses and safety rules to prevent injury!

Materials Needed:

Here is a lesson plan for your records.

Print this Manufacturing Process handout.

Optional Materials:

Print these key terms if you'd like to use them as a reference.

Take a look at these pictures. The red arrows are showing you the direction of the process. What is this process called?

Teaching Tips:

Explore Module Overview

- Students discover the steps taken in the manufacture industry

- Students will be able to explain what the manufacture process is and the steps taken

- Students will practice creating their own laser engraved product after viewing some examples

- Students learn problem solving using robot, software, planning, design, and cost effectiveness of their product

The teacher will check for understanding by asking questions:

Questions

- What is the manufacturing process?

- What steps are necessary?

- What can I plan, research, and create?

Higher order thinking question

- How can I improve the cost effectiveness even more?

Teaching Tips:

Prototype Module Overview

We made some nice looking custom keychains at a very low cost (Arts & Crafts store). Any image you want on keychain.

- Dobot with laser attachment

- A decent size wood board to work on small to big projects. (prevent burning on desks)

- Rectangle wood cut outs (size of keychain)

- Nickel plated screw eyes

Note: Recall all of the safety measures and laser setup steps from Lesson 3.

Product Inspiration

Here is the finished keychain:

We then screwed on a screw eye on top.

To finish out product. We can give our customer a choice of either painting it for them at a cost or they do it for a lower price.

We also had someone here request a mermaid logo. We offered two choices outlined or filled in. The outline can be accomplished using Write & Draw just like you learned in Lesson 3.

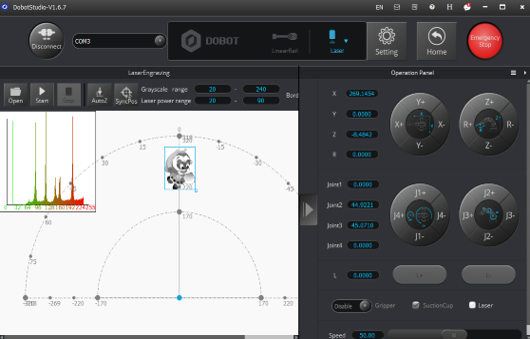

The filled logo was created using the Laser Engraving option on DobotStudio.

Your custom image, whether designed by you or downloaded, must be in the JPG, BMP, or PNG format.

Here is another project idea for you that we did ourselves also. This decorative piece was also bought at a local Arts & Crafts store. It comes a small rope for wall hanging.

1st you place the piece right in the middle front of Dobot on top of the board.

Then we traced some of the markings once again so we know where to place additional pieces.

To get perfect alignment you must pay special attention to detailed measurements on DobotStudio.

When in this mode (Write & Draw) or (Laser Engraving) you will notice that you can see the arm moving (with a spot) on the screen when you use the Operation Panel. Use this tool to help you get your picture perfectly sized with your engravable object.

When alignment was good we started the engraving process. Another successful finished product that can be sold, after we took an idea, created a sketch, researched it, cost effective, designed it, and created it.

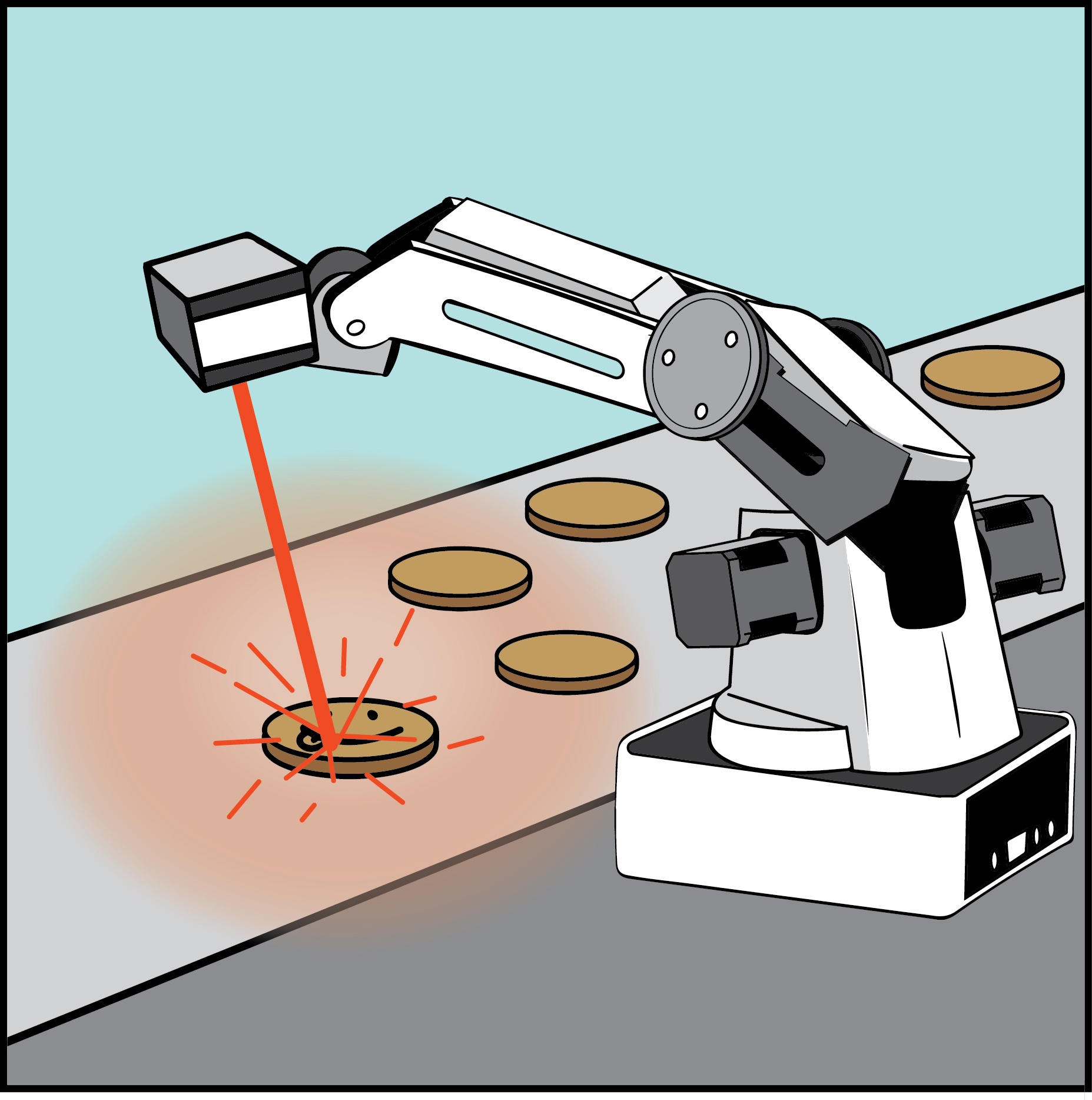

Here is one last project. We made a coaster! A simple precut board with round edges, glued some rubber bumpers, and engraved. As you are designing and creating your new product you are to fill out the handout given to you by your teacher.

Teaching Tips:

Reflect Module Overview

- What is the Manufacturing Process?

- Manufacturing process are the steps through which raw materials are transformed into a final product.

- Are transportation, handling, and storage part of the process? Why or why not?

- Transportation, handling or storage of parts are not under steps of manufacturing process, because these steps are not involved with the change of form of material or dimensions of the part being produced.

- Name at least 3 of the manufacturing processes mentioned.

- Repetitive

- Discrete

- Job Shop

- Process (continuous)

- Process (batch)

- What does REM stand for and what is it?

- Repetitive manufacturing (REM) is the production of goods in rapid succession.

- Describe Discrete manufacturing in your own words.

- is the production of distinct items. Smartphones, cars, and furniture are examples of discrete manufacturing products.

- Job shop is a type of manufacturing process in which small batches of _______________.

- is a type of manufacturing process in which small batches of a variety of custom products are made.

- Describe the Process (batch).

- the product is made in batches or lots.

- What are the 5 emerging technologies that have provided growth in manufacturing employment?

- Cybersecurity

- Advanced Materials

- 3D Printing

- Predictive analytics

- Collaborative Robots

- one type of custom product

- a variety of custom products