Lesson Modules

Teaching Tips:

Observe Module Overview

- Teacher will grab student’s attention by asking them to look at a power point beginning with some question regarding the scenario shown. A lesson about conveyor system will follow. They are to ask themselves what is happening and what technology is being used. While at the same time the teacher will be demonstrating how it’s being used in a real-world situation.

- After video example and power point lesson, students will program the Dobot to simulate the automation of sorting the toxic containers (or other objects) by color using the color sensor, photoelectric sensor, and conveyor belt. A combination of all previous learned material.

- The student’s, after the engagement, should be asking themselves how they can apply what they just learned in future project given by teacher and in the real world.

Lesson Overview

- Ensure the Dobot firmware and software is updated to the latest version. This will reduce troubleshooting.

- This lesson can be done individually or in groups. Depending on size of class or number of robots. If several students per robot, you might want to assign them separate responsibilities for full engagement.

- This lesson can take between 1 to 2 class periods depending on coding knowledge of students with Blockly ,Script, Dobot in general.

- This lesson and skills is considered high and will be built upon to even higher levels in the next lessons.

- Having students start in the Power ON homing position is recommended, so that every student or group has their Dobot(s) start from the same spot.

- Remind students that in this project they are to pick an x,y,z coordinate spot in the conveyor belt where they will be feeding Dobot the containers or cubes. In the lesson example we chose to make the code stop ½ second after detected resulting right in front of color sensor.

- The perfect distance between the object and the photoelectric sensor will need to be determined by students and coded for exact gripper positioning when picking up. The sensor is very sensitive and can detect objects or humans that might pass in front of it.

- When programming remind students about turning on and off the color sensor as they do with the gripper attachment. As well as telling Dobot what port their color sensor and photoelectric sensor is plugged into as there are different models.

Materials needed

Handout for prototyping

Detailed explanation of the code solution

Optional materials

Key factor vocab sheet to print

The Conveyor System

A conveyor system is a common piece of mechanical handling equipment that moves materials from one location to another.

Conveyor systems allow quick and efficient transportation for a wide variety of materials, which make them very popular.

Teaching Tips:

Explore Module Overview

Discuss the key terms with students.

Questions to promote discussion:

- How does a conveyor system work?

- How are they designed and used?

- What is and how are photoelectric sensors used?

Higher order thinking questions:

- How can you fully automate this project by eliminating PICKING of containers by humans?

Key Terms

- Conveyor System – a common piece of mechanical handling equipment that moves materials from one location to another.

- Head Drive Motorized Pulley - pulley that applies force to the belt to drive the system it’s attached to.

- Tail Pulley- pulley at the end of the conveyor opposite the normal discharge end.

- Photoelectric Sensor - used to discover the distance, absence, or presence of an object by using a light transmitter.

Teaching Tips:

Prototype Module Overview

Each group or individual is to program Dobot with the following guidelines:

- Dobot must accurately and safely PICK up a container using the gripper as the photoelectric sensor detects it and stop conveyor

- Dobot must securely transport the container to the color sensor for identification of Red, Green, or Blue.

- Dobot must safely and accurately place down the container inside the circle without touching the outside.

Prototyping Challenge!

DOBOT must do the following:

Dobot must turn ON the belt, as you place the containers, and wait for the photoelectric sensor to detect the object.

Dobot must accurately and safely PICK the container using the gripper and move it above the color sensor to detect color.

Dobot must then securely transport the container to the PLACE handout and the correct storage area.

Dobot must safely and accurately place down the container inside the circle without touching the outside.

If you need some help visualizing the project watch this Lesson 4 video.

Setup

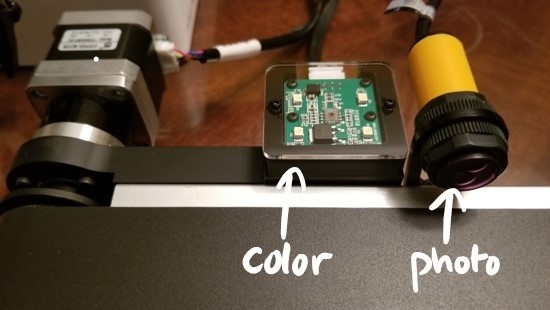

Your setup should look similar to this. Put Dobot in the home position as you start the Blockly/Script code.

Your color and photoelectric sensor should be position and installed as shown.

As you are placing the containers at the other end (tail pulley) place them about ½ inch away from the edge on top facing the sensors.

Teaching Tips:

- What is the definition of conveyor system?

- A common piece of mechanical handling equipment that moves materials from one location to another.

- What does a conveyor system do?

- Allow quick and efficient transportation for a wide variety of materials. (The answer can be any of the following.)

- What do companies see as the most important benefits of a conveyor?

- Conveyors can safely transport materials from one place to another, which when done by human labor would be strenuous and expensive.

- They can be installed almost anywhere and are much safer than using a forklift or other machine to move materials.

- They can move loads of all shapes, sizes and weights. Also, many have advanced safety features that help prevent accidents.

- What kind of industries use conveyor systems? Name 3 of them.

- Mining, automotive, agricultural, computer, electronic, food processing, aerospace, pharmaceutical, chemical, bottling and canning, print finishing and packaging.

- What are the two most common types of conveyor systems?

- Belt and Roller.

- What is the head drive motorized pulley?

- Pulley that applies force to the belt to drive the system it’s attached to.

- What is the tail pulley?

- Pulley at the end of the conveyor opposite the normal discharge end.

- What is a photoelectric sensor?

- Used to discover the distance, absence, or presence of an object by using a light transmitter.

Reflect on your project . How many failed attempts did it take? What was the hardest part?

What new things did you learn during the project?

- Answers will vary

- conveyor movement

- light level

- color

- distance/presence

- Belt and Wheel

- Belt and Roller

- Pneumatic and Roller

- Wheel and Conveyor

- Pulley that applies force to the belt to drive the system it’s attached to.

- Pulley that applies force to the belt to drive the Dobot.